Predator MDC™ for Okuma CNCs

New! Okuma OSP-500 support

Predator MDC fully supports Okuma's next generation OSP-P500 control. Support for the 21.5" and 15" models of the P500M, P500L and P500S series CNCs are included within Predator MDC and Predator MDC Enterprise. The Okuma OSP-500 includes Ethernet communications with every model with an option for RS232 (DNC-B) support. Predator MDC includes support for multiple machine monitoring and data collection protocols including OSP API, MTConnect and OPC UA. One of the following Okuma options must be enabled on each Okuma machine: OSP API KIT, OSP-MTConnect or OPC UA for Machine Tools.

Okuma OSP-500 support has also been added to the Predator CNC Editor, Predator DNC, Predator PDM, Predator Touch HMI, Predator Tracker, Predator Travelers and Predator Virtual CNC.

Complete Okuma CNC support with Predator MDC Software

Leverage the power of Predator MDC with Okuma CNCs to simplify and track CNC machining and productivity via CNC specific manufacturing based data collection.

- Track cycle time, setup time, teardown time, downtimes, idle time, good parts, scrap parts, etc.

- Actual metrics per job, part, operation, traveler, customer, department, shift, user, cell and more

- 30,000+ reports, charts and dashboards within Predator MDC

- Ethernet software based, no special data collection hardware required on P500, P300, P200 and P100 Series

- Hardware or RS232 (User Task 2) based for older Okuma CNC models

Okuma OSP P Series Support

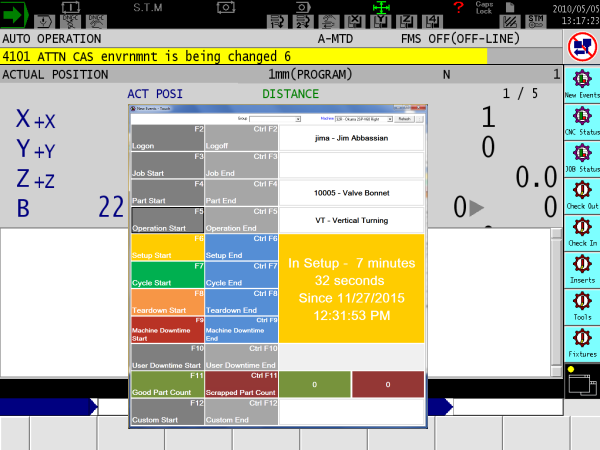

The following 18 optional Predator MDC dialogs can be integrated within the Okuma P500, P300, P200 and P100 CNCs:

- New Events

- View Jobs

- View Parts

- View Real-time Cost Center Status

- View Real-time Customer Status

- View Real-time Department Status

- View Real-time Group Status

- View Real-time Job Status

- View Real-time Location Status

- View Real-time Machine Status

- View Real-time Machine Type Status

- View Real-time OEE Status

- View Real-time Part Status

- View Real-time Report Type Status

- View Real-time Shift Status

- View Real-time Traveler Status

- View Real-time User Status

- View Real-time Work Center Status

Okuma OSP API Support

Okuma OSP API support is included with the purchase of Predator MDC. Okuma OSP APIs have different versions and the specific version installed on each Okuma CNC may vary. In general, newer P series models will have newer Okuma OSP API versions and thus more features. Support for Okuma OSP API v1.0.21, v1.0.15 and v1.0.09 or greater are included within Predator CNC Service. Pricing and installation of the latest Okuma OSP API on specific Okuma CNCs may vary depending on your region and Okuma distributor. Contact the local Okuma distributor as required for additional Okuma OSP API specifics.

NOTE: The Okuma OSP API was previously known as Okuma THINC API. Existing Okuma CNCs will include doccumentation and software referencing the Okuma THINC API.

Predator CNC Service

Leverage the power of Okuma OSP APIs with Predator CNC Service to provide intelligent software based machine monitoring via an Ethernet interface. Predator CNC Service supports machine operation modes, cycle counters, variables, feeds and speeds for all makes and models of Okuma mills, lathes and grinders with P500, P300, P200 and P100 CNCs.

NOTE: The Okuma OSP API was previously known as Okuma THINC API. Existing Okuma CNCs will include doccumentation and software referencing the Okuma THINC API.

The following software based data collection details are supported:

- Cycle Time

- Idle Time

- Automatic Time

- MDI Time

- Feed Hold Time

- Single Block Time

- Emergency Stop Time

- Alarm Time

- Spindle Speeds

- Feed Rates

- Spindle Loads

- Feed Rate Overrides

- Spindle Speed Overrides

- Program Numbers

- Sequence Numbers

- Part Counters

- User Task 2 Variable Values

- Digital Inputs & Outputs

- and more...

Predator MDC supports custom data collection should additional details be required.

Older Okuma CNCs (E Series, U Series, etc.)

Support for older Okuma CNCs are supported two ways. The first option is to use the power of Okuma User Task 2 and G code to support machine monitoring and manufacturing data collection via an RS232 interface. The second option is to use Predator MDC Adapters to monitor electrical signals or sensors on each CNC mill, lathe and grinder. Learn more