Predator MDC™ for Fanuc CNCs

Why use Predator MDC with Fanuc Focas?

Leverage the power of Predator MDC with Fanuc Focas to simplify and track CNC machining and productivity via Ethernet or fiber optic interfaces.

- Track cycle time, setup time, teardown time, downtimes, idle time, good parts, scrap parts, etc.

- Actual metrics per job, part, operation, traveler, customer, department, shift, user, cell and more

- Works with a wide range of Fanuc CNCs

- Ethernet based interface

- Software based, no special data collection hardware required

Fanuc Focas Support

Fanuc Focas support is included with the purchase of Predator MDC.

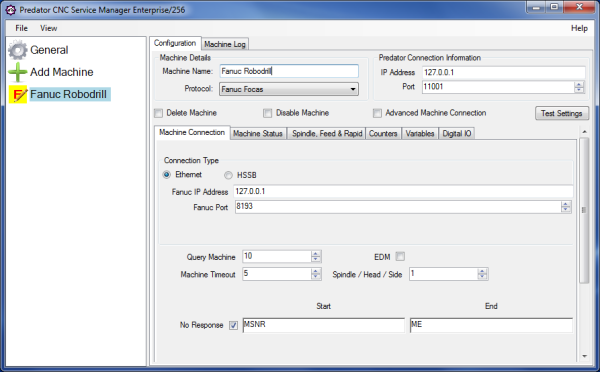

Predator CNC Service

Leverage the power of Fanuc Focas with Predator CNC Service to provide intelligent software based machine monitoring via an Ethernet or HSSB interface. Predator CNC Service supports machine operation modes, cycle counters, variables, feeds and speeds for all makes and models of Fanuc CNC based Mills, Lathes, Routers, Lasers, Grinders and EDMs.

The following software based data collection details are supported:

- Cycle Time

- Idle Time

- Automatic Time

- Edit Time

- Handle Time

- MDI Time

- Feed Hold Time

- Single Block Time

- Emergency Stop Time

- Alarm Time

- Spindle Speeds

- Feed Rates

- Spindle Loads

- Rapid Overrides

- Feed Rate Overrides

- Spindle Speed Overrides

- Program Numbers

- Sequence Numbers

- Part Counter Values

- Custom Macro Variable Values

- Digital Inputs & Outputs

- and more...

Predator MDC supports Fanuc Focas via Ethernet or HSSB. Predator MDC supports custom data collection should additional details be required.

NOTE: Some of the above data collection features require Fanuc options. For example, Fanuc Custom Macro, Fanuc DataServer, HSSB or Fanuc Spindle Load options may have to be purchased and installed by the machine tool builder, machine tool distributor or Fanuc FA.